69 jaw crusher price

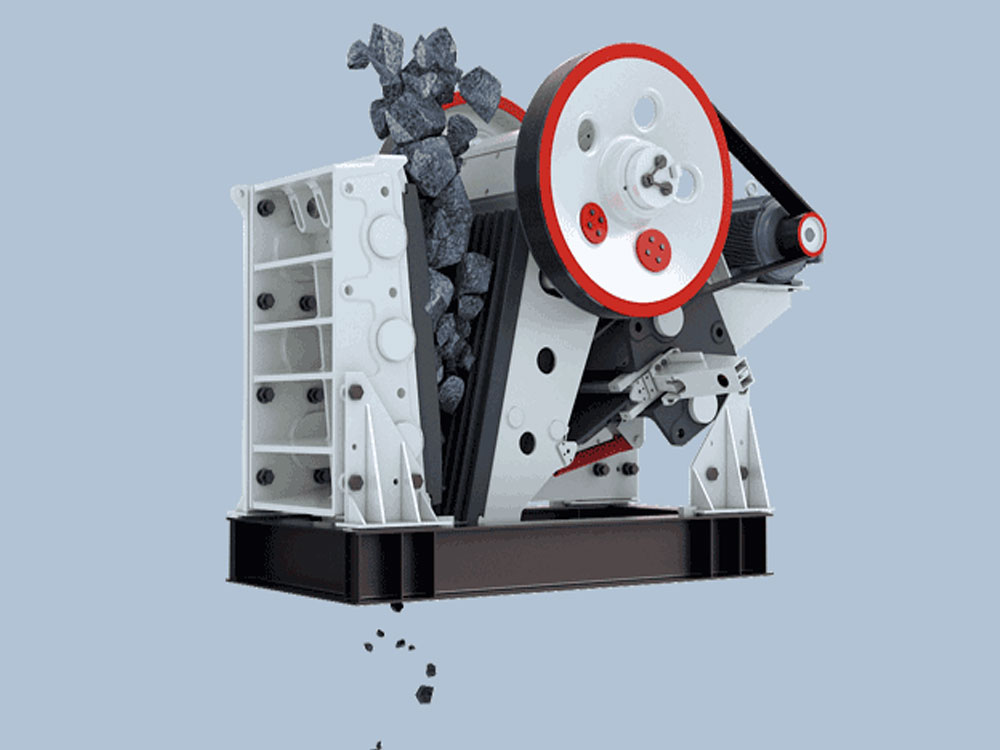

The 69 jaw crusher is a widely used crushing equipment in the market, with the characteristics of simple structure, stable operation and convenient maintenance. The machine consists of the main parts of the movable jaw, fixed jaw, crushing chamber, etc. When working, after the material enters the crushing chamber, it is crushed by the compression between the movable jaw and the fixed jaw. Its main advantages are strong crushing force, large processing capacity, and can meet the crushing needs of various materials. The 69 jaw crusher is suitable for coarse crushing of various ores and stones, especially medium-hard materials such as granite, limestone, and ore, and can easily cope with materials with high compressive strength. The machine has a high crushing ratio, a large feed particle size, and a uniform discharge particle size, which is easy to control. The design of the equipment takes into account the convenience of operation, is equipped with an advanced electric control system, and can effectively reduce noise and vibration during the entire production process, thereby improving the comfort of the working environment. In the actual production process, the 69 jaw crusher has won the favor of a large number of customers with its superior performance and stability. Whether it is large-scale mining or small and medium-sized construction, it can efficiently complete the crushing operation and greatly improve production efficiency. Whether from the manufacturing process of the equipment or from the reliability in long-term use, the 69 jaw crusher is a very cost-effective equipment.

69 jaw crusher Working principle

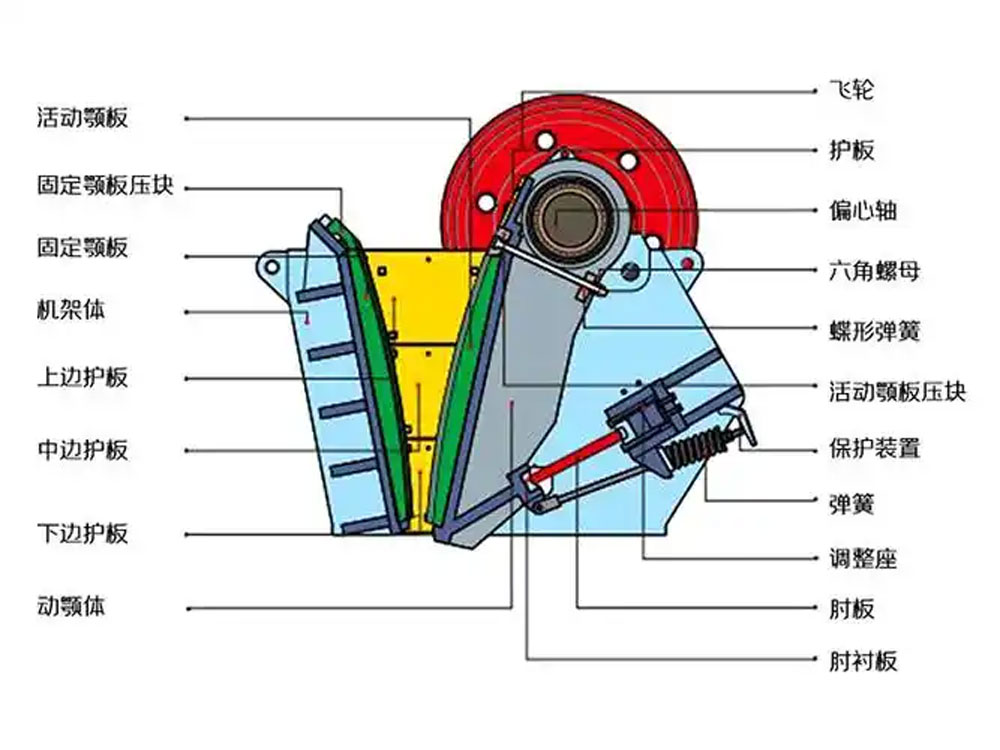

The working principle of the 69 jaw crusher is mainly based on the relative movement between the material and the two jaw plates. After the crusher is started, the motor drives the eccentric shaft to rotate through the belt, and the eccentric shaft drives the movable jaw to make a reciprocating swinging motion. The material enters the crushing chamber from the feed port, and is compressed, bent and sheared under the action between the movable jaw and the fixed jaw, thereby crushing it into smaller particles. When the movable jaw swings close to the fixed jaw, the material is squeezed and crushed, and the crushing force is the largest at this time; when the movable jaw swings away from the fixed jaw, the material in the crusher cavity is discharged. The degree of material crushing mainly depends on the distance between the jaw plates and the feed particle size. When the material is crushed to the required particle size, the crusher controls the final discharge particle size by adjusting the size of the discharge port. The deep cavity design adopted by the machine can ensure that larger materials enter the crushing chamber, improve the processing capacity of the crusher, and make the residence time of the material during the crushing process shorter, reducing the wear of the equipment. During the overall operation of the machine, it is stable and reliable, with low noise, and reduces pollution to the environment. In short, the 69 jaw crusher is a very suitable equipment for coarse crushing operations. It has strong crushing capacity, high processing capacity and excellent working efficiency. It is widely used in various mining, construction, metallurgy and other industries.

69 jaw crusher Advantages

High crushing ratio, strong and durable

The 69 jaw crusher has a high crushing ratio, which can achieve efficient crushing of larger particle size materials, reduce production costs and improve crushing efficiency. The equipment is made of high-quality steel, the body structure is stable, can withstand large impact loads, and ensure the long-term stable operation of the equipment.

Easy maintenance, smooth operation

The 69 jaw crusher is reasonably designed and easy to maintain. Most parts of the body can be easily disassembled and replaced, which greatly reduces the downtime and maintenance time of the equipment. The use of advanced electronic control system and eccentric shaft design makes the crusher run more smoothly, with low noise and small vibration, extending the service life of the equipment.

Strong adaptability and high efficiency

The equipment can adapt to various hardness ores and stones, especially suitable for crushing materials of medium hardness and below, such as granite, limestone, etc. Its design concept and structure have significantly improved the crushing efficiency of the equipment, and can more efficiently complete the crushing task of large quantities of materials.

Energy saving and environmental protection

The 69 jaw crusher has a high energy utilization rate and low power consumption operation, which reduces energy consumption in the production process and has good environmental performance.

Versatility and easy operation

In addition to traditional ore crushing, the 69 jaw crusher can also be used in construction waste treatment, road construction and other fields, and has a wide range of application prospects. The equipment operation interface is simple and clear, easy to control and operate, and even operators without rich experience can easily get started.

69 jaw crusher Cases and Technical Parameters

| Feed inlet size | 600×900 mm | Processing capacity | 50-400t/h |

| Maximum feed size | 500 mm | Motor power | 75-110kW |

| Discharge size | 10-90 mm | Overall dimensions | 2780×2250×2200 mm |

69 jaw crusher Cases and customer testimonials

A mining company has achieved significant economic benefits after using the 69 jaw crusher. The company needs to process a large amount of medium-hard stone and has high requirements for output and discharge particle size. The 69 jaw crusher successfully solved their problems of low production efficiency and frequent equipment maintenance with its high crushing ratio and high output. The stability of the equipment has reduced the company's downtime and greatly improved production capacity.

Customer Mr. Zhang said: "We have chosen the 69 jaw crusher and have used it for two years. The machine runs very stably, and there are basically no major failures. Maintenance is also very convenient, and production efficiency has been significantly improved. We are very satisfied with this equipment."

In addition, customer Mr. Li also shared their experience: "We are a medium-sized construction engineering company. The 69 jaw crusher has helped us improve our stone crushing production capacity and reduce production costs, especially in terms of environmental protection and energy saving."

These customer feedbacks show that the 69 jaw crusher performs very well in various industries and is an efficient, economical and reliable crushing equipment.