C106 Jaw Crusher Contributes to Green Development

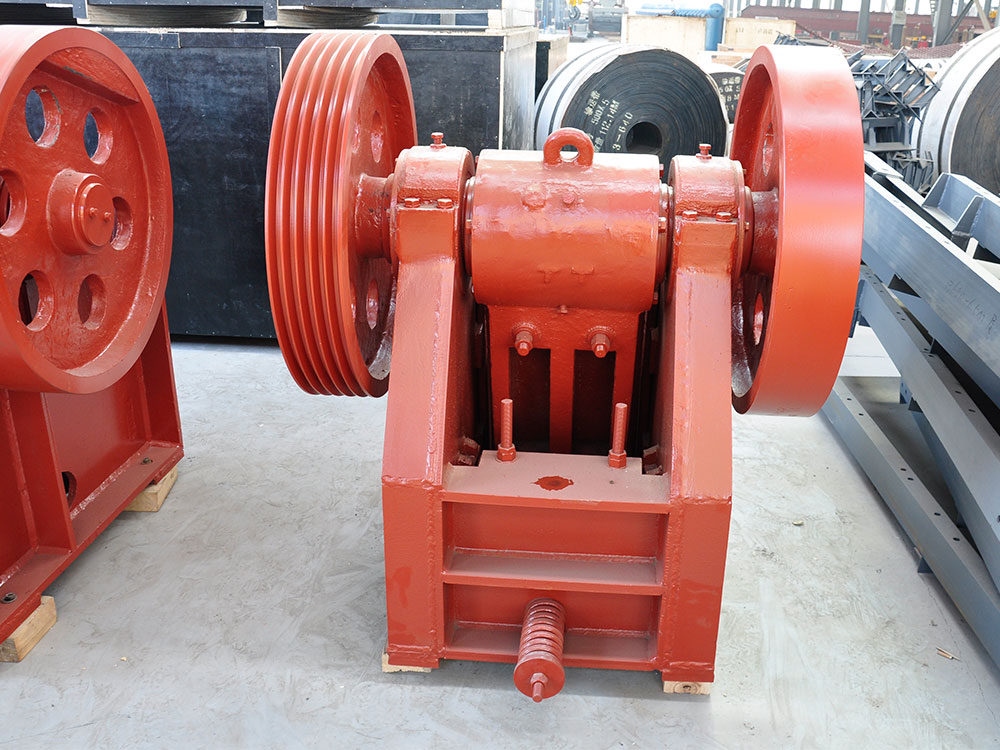

C106 Jaw Crusher is indeed a crushing equipment with outstanding performance. With its advanced driving device and well-designed crushing chamber, it can easily cope with different working conditions and materials. The crushed materials have uniform particle size and regular shape, which undoubtedly provides a strong guarantee for the efficiency and quality of subsequent processing.

The equipment not only has strong crushing capacity, but also has high crushing efficiency, which can quickly process a large amount of materials to meet the fast-paced needs of production lines. Its wide range of applications, such as mining, building materials, chemical industry, water conservancy, etc., also fully proves its strong strength and adaptability.

When purchasing C106 jaw crusher, we do need to carefully consider the production demand and choose the right model and specification of the equipment. At the same time, the quality of equipment and after-sales service of regular manufacturers are also important factors that cannot be ignored. Only by ensuring the reliable quality and long service life of the equipment, we can have more peace of mind and efficiency in the production process.

C106 Jaw Crusher Contributes to Green Development Applications

In mining, C106 jaw crusher shows its powerful crushing ability, which can easily cope with various hardness of ores, such as granite, basalt, iron ore and so on, providing just the right raw materials for subsequent ore processing. In the building materials industry, it also shines, commonly used in crushing limestone, pebbles and other materials, these crushed materials become an important basis for the production of concrete, cement and other building materials. Not only that, C106 jaw crusher also plays an important role in the crushing of materials in the chemical industry, water conservancy, smelting and other industries, and perfectly meets the stringent requirements of these industries on the particle size of raw materials. In the field of transport, especially in road construction, it even crushes large rocks or construction wastes into high-quality stone materials suitable for road construction, such as road base materials, pavement materials and recycled aggregates, contributing to road construction. In addition, C106 jaw crusher is also involved in railway construction, crushing natural rocks into the size that meets the standard of railway ballast, showing its wide application prospects.

C106 Jaw Crusher Contributes to Green Development Advantages

Powerful crushing capacity

With its advanced design and flexible configuration, the C106 Jaw Crusher is capable of meeting the most demanding primary crushing requirements, and exhibits strong power even in the face of the toughest materials. Its unique crushing chamber design further improves the material throughput and crushing ratio, ensuring efficient crushing results.

Wide range of applications

C106 Jaw Crusher is not only suitable for traditional fields such as mines and gravel quarries, but also widely used in many industries such as building materials, chemical industry, water conservancy and smelting. It is capable of crushing ores and rocks of various hardnesses, such as granite, basalt, iron ore, etc., to provide suitable raw materials for subsequent processing.

Excellent particle size and high productivity

The materials crushed by this equipment have uniform particle size and excellent grain shape, which meet the requirements of subsequent processing. At the same time, its high production efficiency can greatly improve the overall production capacity, creating more economic benefits for the enterprise.

Stable and reliable operation

C106 Jaw Crusher adopts advanced manufacturing technology and high-quality components to ensure the stable and reliable operation of the equipment. With low failure rate and short downtime, it can run continuously for a long time, providing a strong guarantee for the production of enterprises.

Flexible adjustment, strong adaptability

The equipment usually has an adjustable crushing chamber outlet size, which can adjust the size of the crushed product according to the need, in order to adapt to the needs of different industries on the size of raw materials. This flexibility allows the C106 jaw crusher to be used in a number of industries to maximise its value.

C106 Jaw Crusher Contributes to Green Development Working Principle

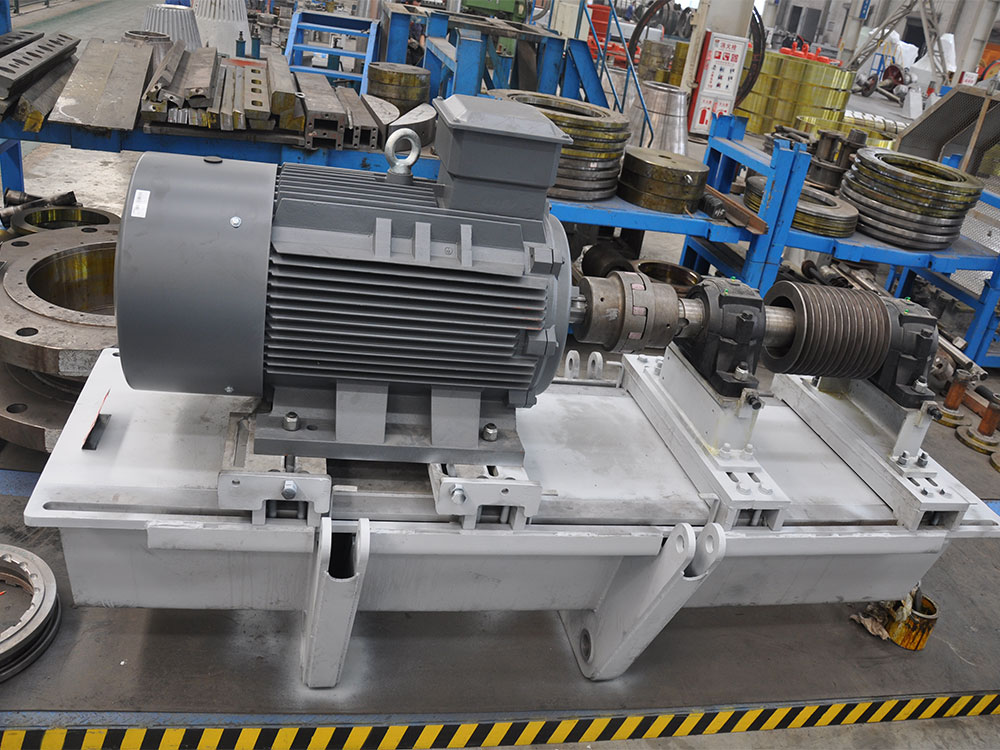

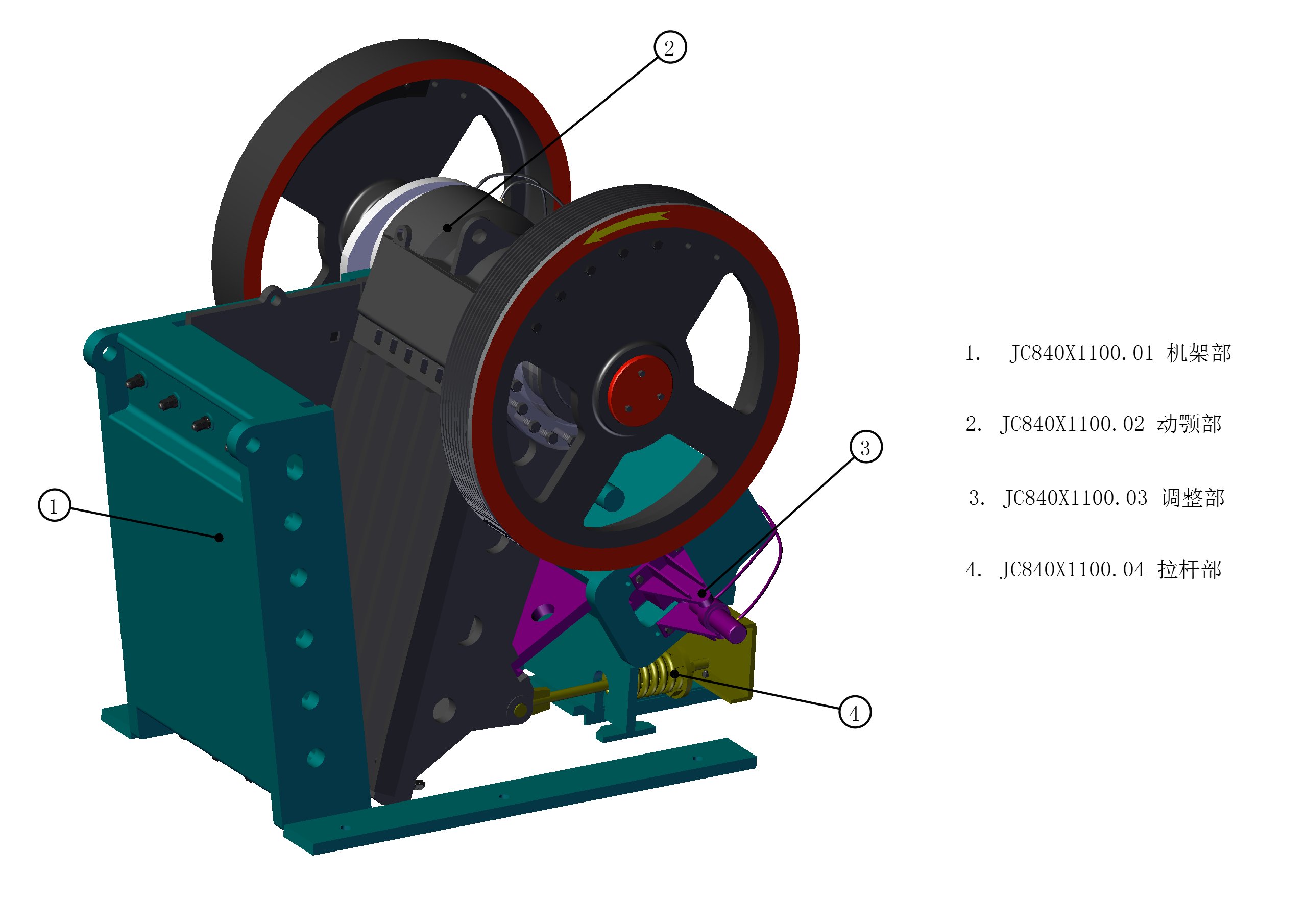

The working principle of C106 jaw crusher is quite exquisite. It consists of two core components, the fixed jaw plate and the movable jaw plate. The movable jaw plate is cleverly connected to the driving device through the eccentric shaft, so that it can move up and down or back and forth flexibly.

When the movable jaw plate slowly approaches the fixed jaw plate, the crushing stroke of the crusher starts. The slit between the two jaws gradually narrows, exerting a huge squeezing pressure on the material. Under the action of this pressure, the material undergoes multiple tests such as crushing, splitting and bending, and gradually breaks into fine particles. It is worth noting that during the crushing process, the pressure on the material is cleverly concentrated in a smaller area, which makes the crushing process more efficient.

Once the movable jaw has completed its crushing task, it will gracefully move in the opposite direction with the help of an eccentric shaft or other mechanism to make room for the discharge of the material. At this point, the crushed material will naturally slide down from the discharge opening under the action of gravity, and the whole crushing process will be successfully completed.

In addition, C106 Jaw Crusher also has an extremely practical function - adjustable crushing chamber. Users can easily adjust the outlet size of the crushing chamber according to actual needs. This design enables the crusher to accurately control the size of the final product, thus meeting the diverse needs of different industries for raw material size.

C106 Jaw Crusher Contributes to Green Development Technical Parameters

| speed | 280 rpm | Power | 110 kW |

| Weight | 15 650 kg | width | 1 060 mm |

| depth | 700 mm | closed side | 70 mm-200mm |