Energy saving and environmental protection CJ411 jaw crusher

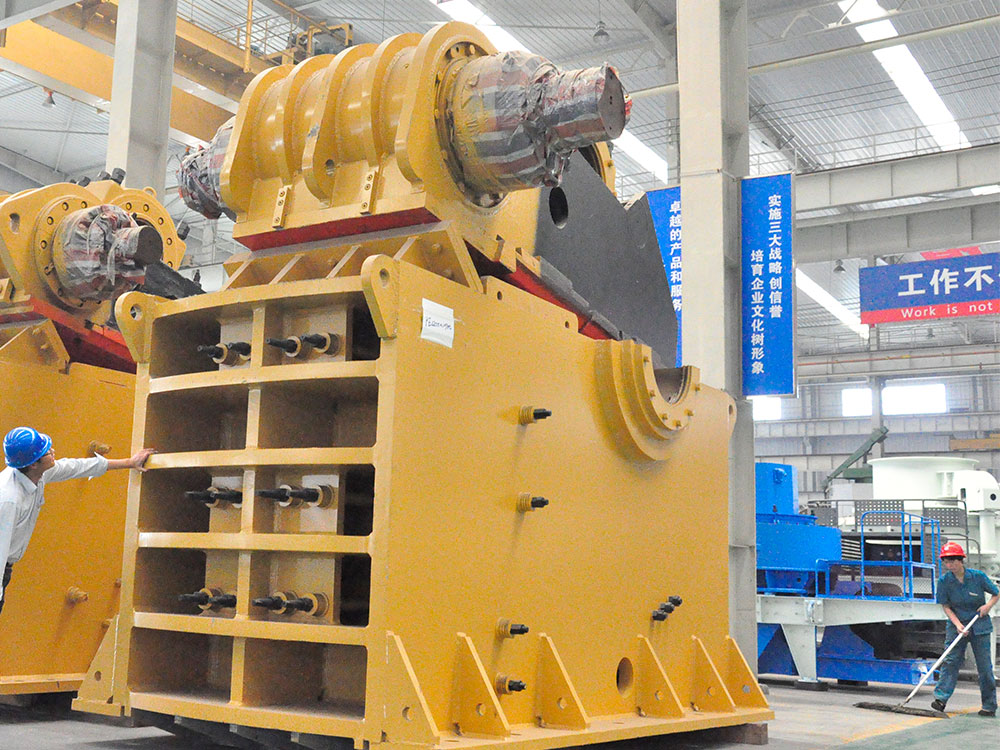

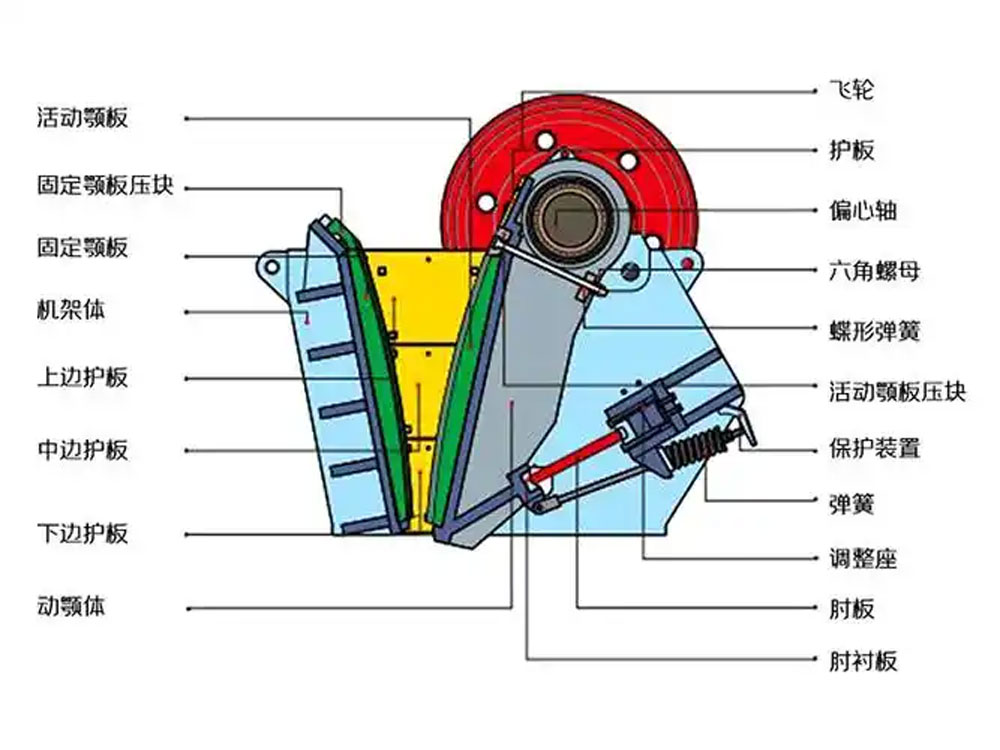

CJ411 Jaw Crusher is a high-performance crushing equipment designed for mining, construction, metallurgy and other industries, which is suitable for crushing ores and rocks of various hardnesses, such as granite, basalt, limestone and so on. Its excellent crushing efficiency, robust structural design and reliable operating performance make it an ideal choice for medium and large crushing operations.CJ411 Jaw Crusher adopts the classic jaw crushing structure, which is mainly composed of fixed jaw, movable jaw, eccentric shaft, connecting rod and adjusting device. When working, the motor drives the eccentric shaft to rotate through the belt, which drives the movable jaw plate to do periodic reciprocating motion, so that the materials are squeezed, sheared and impacted in the crushing cavity, thus achieving crushing. By adjusting the size of the discharge opening, the granularity of the finished product can be controlled to meet different production requirements. Adopting whole welded structure ensures equal strength in all directions and excellent durability against impact loads. The deep and symmetrical design, together with the optimised meshing angle, can maximise the crushing ratio and output. The fixed jaw plate and movable jaw plate form the crushing working area, and the movable jaw plate is connected to the driving device through the eccentric shaft to realise up and down movement to squeeze and crush the materials.

Energy saving and environmental protection CJ411 jaw crusher Applications

CJ411 Jaw Crusher is a key primary crushing equipment in mining operations, specialising in coping with the task of coarse crushing of large ores. It is suitable for the coarse crushing process of metal ores (such as iron ore, copper ore, gold ore, etc.), and is able to reduce the raw ores to the appropriate size and prepare qualified raw materials for subsequent grinding and beneficiation operations. At the same time, it can also process non-metallic ores (e.g. limestone, granite, marble, etc.) to produce construction aggregates or industrial raw materials. Its wide feed opening (1100 x 850mm) can easily cope with raw ores up to 750mm, and its processing capacity ranges from 200 to 600 tonnes/hour, which fully meets the needs of high-production mines.

In the production line of sand and gravel aggregate, CJ411 Jaw Crusher plays an important role in converting natural rocks or blasted stones into aggregate that meets engineering standards. As a primary crushing equipment, it can crush large rocks into medium-sized gravel, which is suitable for the production of basic aggregates for highways, bridges and high-rise buildings, covering a wide range of materials, such as granite, basalt, river cobbles, concrete waste and so on. By adjusting the discharge opening, the size of the finished product can be controlled (generally between 100-300mm), perfectly adapted to the subsequent fine crushing equipment.

In metallurgical industry, CJ411 Jaw Crusher is an important tool for pre-treatment of materials before smelting. It can effectively crush ores with high hardness (e.g. iron ore, manganese ore) and provide raw materials with suitable particle size for ball mill. At the same time, it can also process smelting slag and realise the crushing and reuse of large slag. Its high-strength structural design and wear-resistant jaws ensure the durability and long service life of the equipment when dealing with high hardness materials.

In large-scale infrastructure construction projects such as railways, highways and water conservancy, the CJ411 Jaw Crusher is able to achieve instant processing of stone materials on site. In construction in mountainous or remote areas, it can directly crush mountain rocks for roadbed filling. In water conservancy projects, it can crush natural stone to produce the coarse aggregate required for concrete. The compact structure of the equipment is convenient for transport and on-site installation, perfectly adapting to various complex working conditions.

In addition, with the increasing awareness of environmental protection, CJ411 Jaw Crusher also plays an important role in the field of construction waste and industrial waste recycling. It can crush recycled building demolition waste (such as concrete blocks and bricks) to produce recycled aggregates. At the same time, it can also process industrial solid waste (such as steel slag and furnace slag) to reuse resources. Its energy-saving design and modular structure not only reduces energy consumption, but also facilitates equipment maintenance and component replacement.

Energy saving and environmental protection CJ411 jaw crusher Advantages

High capacity and efficiency

The CJ411 Jaw Crusher has a wide feed opening (1045 x 840mm) and is capable of handling large materials with a maximum feed size of 750mm. Its deep and symmetrical crushing chamber design and optimised meshing angle enable the machine to maximise the crushing ratio and output during the crushing process. The hourly output can reach 150~565 tonnes, which effectively meets various large-scale production demands.

Stable and durable, low maintenance cost

The crusher adopts a heavy-duty design, and the frame body is welded as a whole to ensure equal strength in all directions and excellent durability against impact loads. This design allows the CJ411 Jaw Crusher to operate stably under severe working conditions, reducing downtime and maintenance costs. At the same time, the jaw plate has little wear and tear, which further extends the service life of the equipment.

Flexible adjustment and adaptability

The CJ411 Jaw Crusher has an adjustable outlet size of the crushing chamber, which means that users can easily adjust the crushing size of the machine according to different production needs, so as to produce products that meet specific requirements. This flexibility allows the machine to perform at its best in a wide range of application scenarios.

Energy-saving and environmentally friendly, in line with the requirements of green production

With the growing awareness of environmental protection, green production has become an important trend in various industries, and the CJ411 Jaw Crusher has been designed with energy saving and environmental protection considerations in mind. By optimising the structure of the crushing chamber and improving the crushing efficiency, the CJ411 Jaw Crusher effectively reduces the energy consumption and emissions, which is in line with the current requirements of green production.

Energy saving and environmental protection CJ411 jaw crusher Working Principle

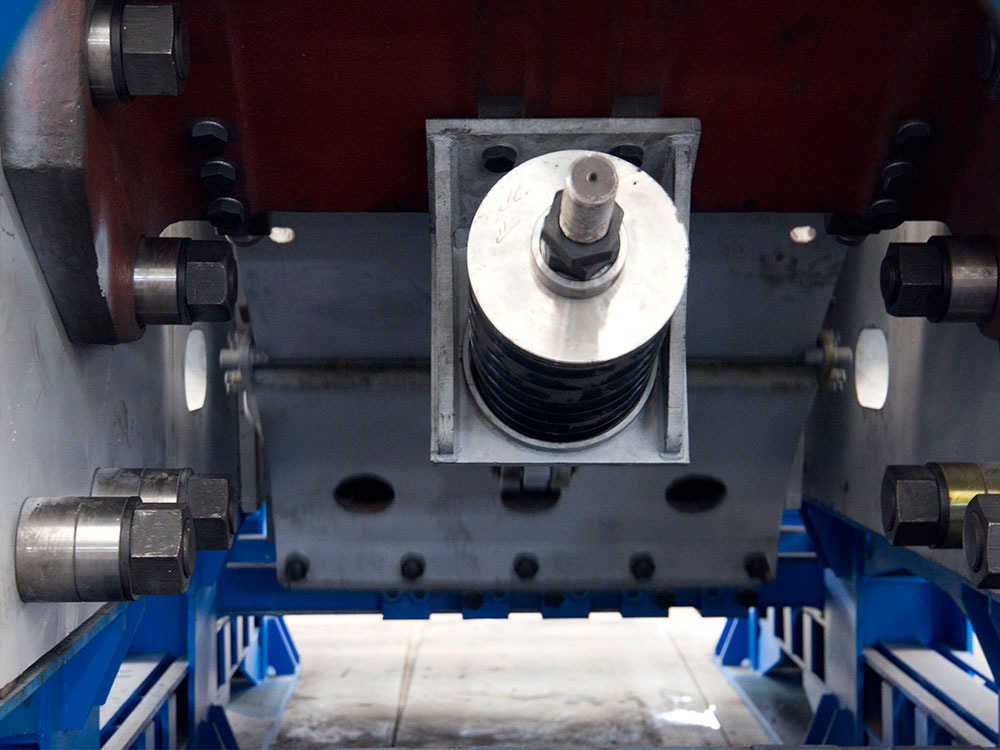

CJ411 Jaw Crusher is mainly composed of fixed jaw plate, movable jaw plate, eccentric shaft, driving device and other key components. When the motor is started, the eccentric shaft is driven to rotate through the pulley drive. The rotation of the eccentric shaft drives the movable jaw plate to reciprocate up and down.

During the downward movement of the movable jaw plate, the material is put into the crushing cavity and subjected to the strong squeezing pressure between the fixed jaw plate and the movable jaw plate. As the movable jaw plate continues to move downward, the slit between the two jaw plates gradually shrinks, and the pressure on the material gradually increases until it exceeds its bearing strength and crushes.

When the movable jaw completes a downward movement, it will move upward by the action of eccentric shaft, at this time, the material in the crushing cavity is crowded and gradually discharged from the discharge port. After that, the movable jaw plate moves downward again to start the next crushing cycle.

The outlet size of the crushing chamber of CJ411 Jaw Crusher is adjustable, so users can control the size of crushed materials by adjusting the outlet size of the crushing chamber according to the actual production requirements.

During the whole crushing process, CJ411 Jaw Crusher ensures efficient crushing and continuous discharge of materials with its high efficiency and stable working performance, which provides strong support for material processing in mining, construction and other fields.

Energy saving and environmental protection CJ411 jaw crusher Parameters

| Capacity | 200-600 t/h | Feed opening | 1,045 x 840 mm |

| power | 110 kW | Weight | 22,800 kg |

| Feed size | 750.000 mm | range | 75.0 - 225.0 mm |