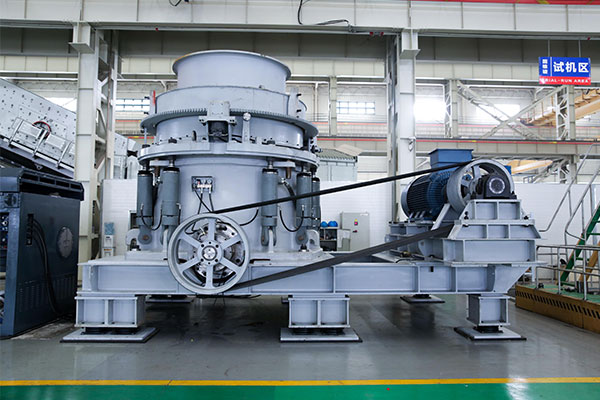

lT 1100 Cone Crusher powerful and Compact

Designed specifically for complex crushing tasks, the LT 1100 cone crusher is crafted by a professional manufacturer and performs particularly well in the fields of resource recovery and construction demolition waste processing. The technical highlight of this equipment is its innovative crushing chamber design, which greatly promotes the efficient crushing of materials and ensures the high-quality form of the finished product. Its design fully considers the diversity of feed particle sizes, while allowing users to flexibly adjust the discharge particle size according to actual needs, improving the flexibility and adaptability of operations. The LT 1100 cone crusher integrates the latest crushing technology, which not only ensures high output output, but also significantly reduces energy consumption. Its sturdy and durable structure, convenient adjustment mechanism and economical use cost make it an ideal choice for large-scale stone processing and The ideal solution in the field of mining crushing.

lT 1100 Cone Crusher Applications

With its excellent crushing performance and wide application potential, the LT 1100 Cone Crusher has demonstrated its extraordinary strength in many crushing operations, especially in the field of recycling and demolition waste treatment. Its efficient crushing capacity ensures that waste materials can be quickly converted into particles that can be reused or safely landfilled, promoting the recycling of resources and environmental protection. In addition, this model is also the core equipment of industries such as large-scale stone production, mining, and construction waste management, providing strong support for the efficient operation of these fields.

The wide adaptability of the IT 1100 Cone Crusher is reflected in its wide application across multiple key fields:

1、Mining field: dedicated to the efficient crushing of various ores such as iron ore, copper ore, and gold ore.

2、Building materials industry: Assist in the crushing and processing of raw materials such as limestone and gypsum, and improve the quality of building materials products.

3、Metallurgical industry: Effectively handle metallurgical waste such as slag and steel slag, and promote resource recycling and reuse.

4、Transportation infrastructure: Provide high-quality crushed stone for the construction of transportation facilities such as roads and railways.

5、Environmental protection industry: Actively participate in the treatment of waste construction waste and industrial waste, and promote the progress of environmental protection.

lT 1100 Cone Crusher Advantages

Optimized crushing chamber design

The LT 1100 Cone Crusher adopts a unique crushing chamber design to ensure that the material is evenly and effectively crushed during the crushing process, thereby achieving efficient material crushing and excellent product shape. This design not only improves crushing efficiency, but also reduces wear and energy consumption.

Wide range of feed size

This model can handle materials of various particle sizes, with a wide range of feed size to meet the crushing needs of different users. Whether it is large ore or fine particles, the LT 1100 Cone Crusher can easily handle it.

Adjustable discharge size

The discharge size is one of the important parameters in the crushing operation. The LT 1100 Cone Crusher can achieve precise control of the discharge size through a simple adjustment device to meet the user's needs for products of different particle sizes.

Advanced crushing technology

This model adopts advanced crushing technology, such as the lamination crushing principle, so that the material is subjected to uniform extrusion and shear force during the crushing process, thereby improving the crushing efficiency and product quality. At the same time, this technology also helps to reduce energy consumption and noise levels.

High output, low energy consumption

LT 1100 Cone Crusher is famous for its high output and low energy consumption. It can minimize energy consumption costs while ensuring the crushing effect, bringing considerable economic benefits to users.

Reliable structure and convenient adjustment

The structure of this model is reasonably designed, compact and durable, and the key components are made of high-strength materials, which ensures the long-term stable operation of the equipment. At the same time, the adjustment and maintenance of the equipment are also very convenient and fast, reducing the user's operating costs and downtime.

lT 1100 Cone Crusher Working Principle

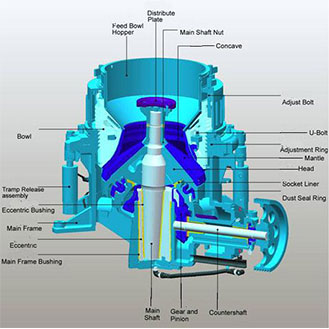

The IT 1100 Cone Crusher inherits the classic design concept of cone crushers. Its working principle is a subtle combination of the interaction between rotational power and static support, achieving efficient material crushing through a precisely controlled mechanical process. The following is a detailed explanation of the working principle of the equipment:

The raw material first enters the crushing chamber through a carefully designed feed port. The size and shape of the feed port are optimized to ensure that the material can enter the crushing area smoothly and orderly, laying the foundation for subsequent efficient crushing. Once the material enters the crushing chamber, its core component, the rotating crushing cone, begins to rotate under the drive of a powerful motor. This rotational action interacts with the liner fixed in the crusher housing to form a strong extrusion and shear force field. The material is repeatedly squeezed and sheared in this force field until the required degree of crushing is achieved. This stage not only reflects the high crushing efficiency of the equipment, but also ensures the high quality of the crushed material. After being fully crushed, the material has a particle size and shape that meet the preset requirements, and then it is smoothly discharged from the crushing chamber through the discharge port. The size of the discharge port can be precisely adjusted according to actual needs through a hydraulic adjustment device, thereby achieving effective control of the product particle size. This flexibility ensures that the IT 1100 Cone Crusher can adapt to a variety of crushing needs and provide users with customized solutions. In order to ensure the stable operation and efficient output of the equipment, the IT 1100 Cone Crusher is also equipped with an advanced intelligent control system. The system can monitor the operating status of the equipment in real time, including key parameters such as motor speed, crushing chamber pressure, and discharge port size, and automatically adjust the working status of the equipment based on real-time data. In addition, the system can also warn of potential failure risks in advance and provide users with timely maintenance suggestions to ensure that the equipment is always in the best operating condition.

lT 1100 Cone Crusher Technical Parameters

| Engine | 224 kW (300 hp) | Feed opening | 1,040 x 800mm (41” x 31”) |

| Weight | 32,000 kg (71,000 lbs) | Width | 2,550 mm (8'4") |

| Height | 3,400 mm (11'2") | Length | 14,850 mm (49') |

| Operating weight | 52 t | Crusher opening length | 0.22 m |

| Transport length | 18.5 m | Transport width | 3.5 m |

| Transport height | 3.8 m | Model series | Nordberg |