Crawler-Mounted Mobile Rubble Recy-cling Plant Screening & Sifting Unit

Customer: Heijmans B. V.

Rosmalen,Netherlands

Plant Description

The crushing plant is in a position to generate a defined end product within one unit. This means that both the scalping of the feed material prior to the comminution process as well as the screening of the crusher product afterwards are incorporated into the process. All the equipment required for the treatment of rubble, concrete and broken road paving is accommodated on a crawler-mounted chassis. This design enables the plant to be deployed directly at the site where the feed material originates.

In the screening & sifting unit, the crusher product (0 – 40 mm) is screened off at 22 mm, the fraction 22 – 40 mm which is contaminated with light material such as paper, polystyrene, wood, etc. is cleaned of these inclusions. There is a facility for discharging the clean fractions together or separately. The screening & sifting plant can also be operated on its own as well as together with the crawler-mounted crushing plant.

Technical Data – Crushing Plant

Feed material: building rubble, concrete and broken road paving

Feed size: lumps 0 – 600 x 500 x 500 mm or

slabs 0 - 1,200 x 1,000 x 250 mm

Capacity: up to 250 tons/hr according to type of feed material

Scalping: eccentric screen separating at 40 mm and 10 mm

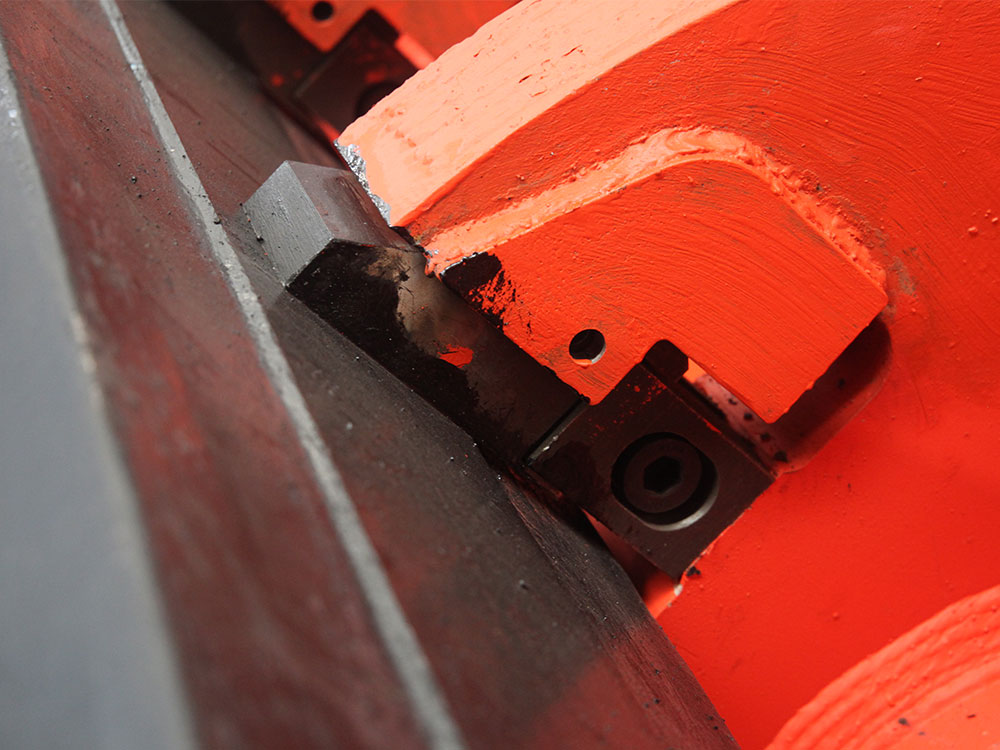

Crusher: HAZEMAG Impactor Type AP-PH 1214

Inlet: height: approx. 940 mm, width: 1,360 mm

Installed drive rating: 160 kW

Crusher product: 0 – 40 mm with approx. 4 – 8 % oversize

Control screening: screening-off at 40 mm

Installed power: 450 kVA three-phase diesel generator

Total weight: approx. 69,800 kgs

Technical Data – Screening & Sifting Plant

Material feed size: 0 – 40 mm

Capacity: 200 tons/hr

Screen unit: free-swinger 1,400 x 5,000 mm

Sifter: drum, 1,000 mm diameter x 1,600 mm wide

Product: 0 – 16 mm, 16 – 40 mm or 0 – 40 mm

the 16 – 40 mm fraction has been cleaned

Installed power: 41 kW

Total weight: 20,000 kgs